Check out our new Robotic Welding website Robotic Welding Cells from Industrial Robotix

The welding systems we design and build are configured around your process requirements. We utilize the latest CAD/CAM design and Robot Simulation Software to create a system that is both efficient and cost-effective.

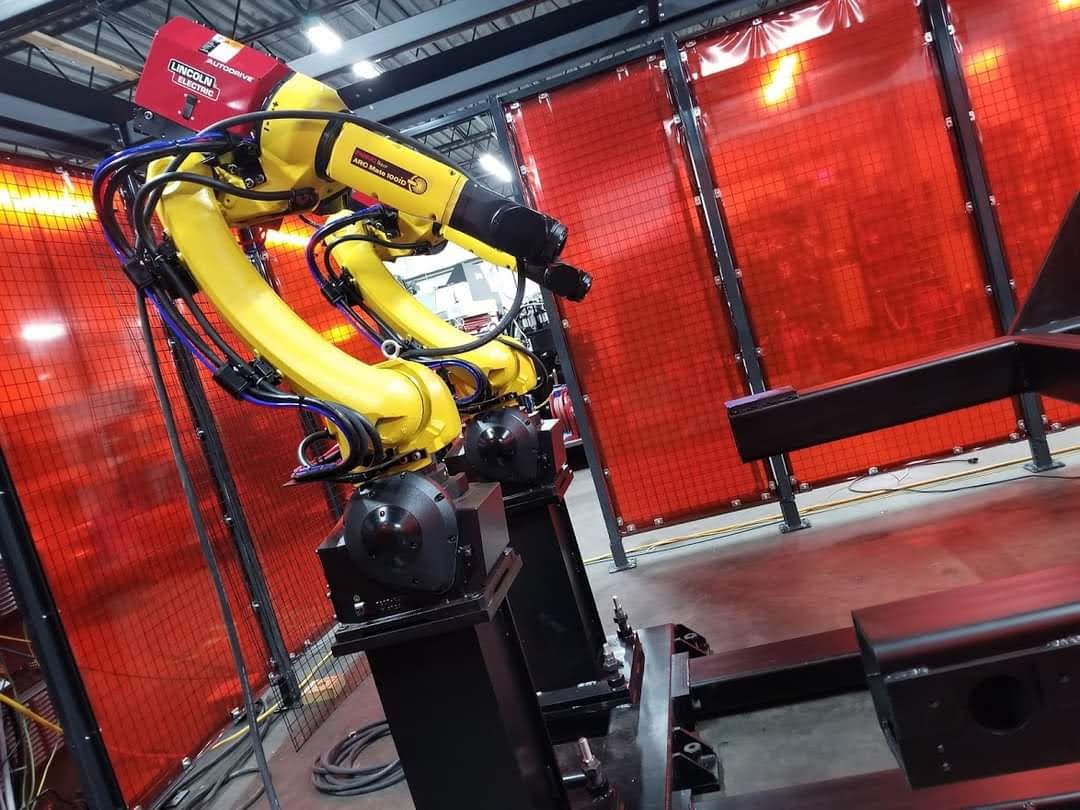

With Fanuc Robotics or Yaskawa Motoman we ensure that your system is built to today's latest ANSI/RIA standards. All controls are dual-channel, all perimeter guarding and safety meets or exceeds the latest standards.

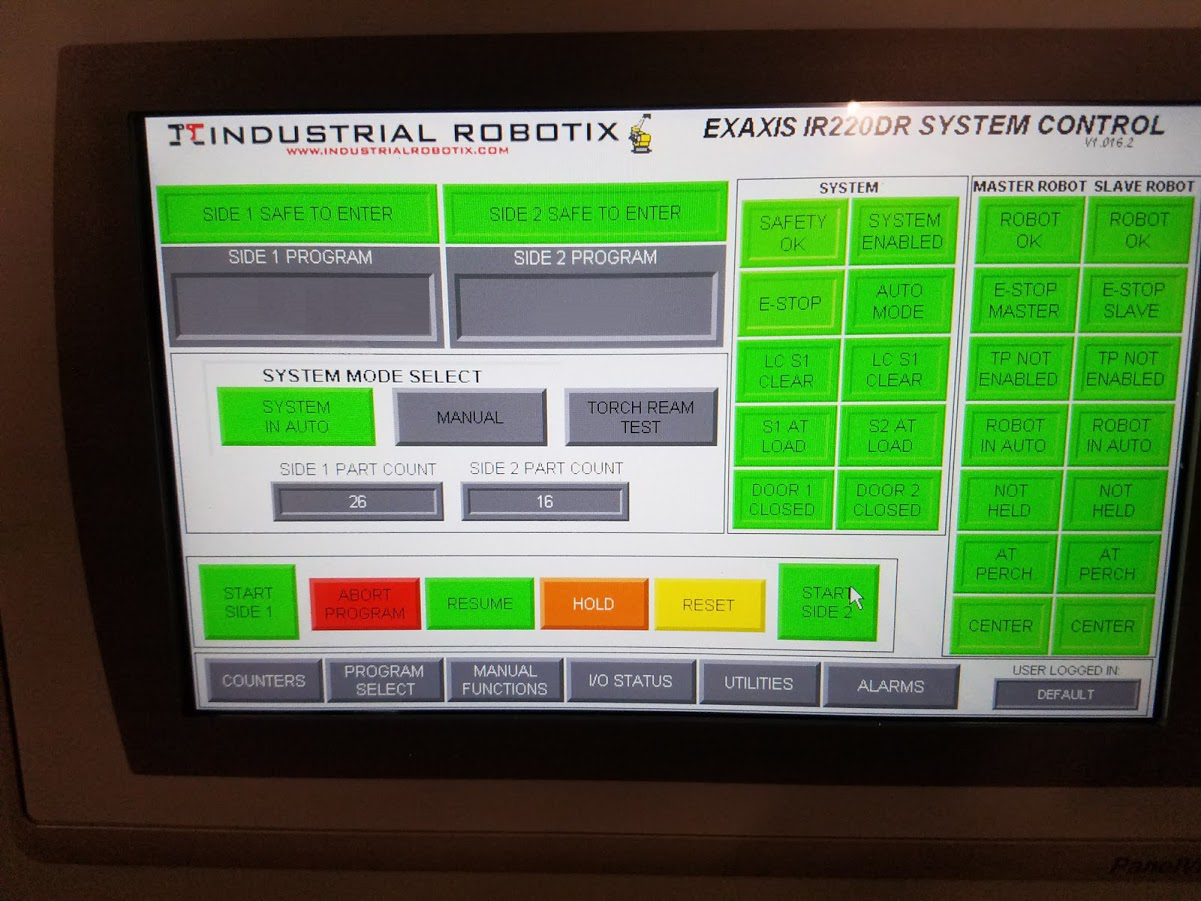

We utilize the latest safety control PLC system from Allen/Bradley. Each system includes a 9" color HMI, full Ethernet I/P communication, CompactGuardLogix PLC system, and more.

Budget systems utilize the robot's safety controls and a standard push-button operator stand.

Choose from many of the options below:

- Custom or Pre-Engineered layouts

- Single servo headstock / tailstock

- Dual servo headstock / tailstock

- Dual-axis Tilt/Rotate positioners

- Dual-axis drop-center positioners

- Single-axis turn tables

- Three-axis turn tables (sweep with dual headstock/tailstock)

- Three-axis ferris wheel

- Single or dual table

- Multi or single zone

- Smoke removal systems and shrouds

- Single or multi-arm

Our welding cells and positioners are designed and manufactured in-house on some of the newest state-of-the art equipment such as Okuma M560V machining center, Okuma L300MYM Y-axis turning center, Omax Waterjets, Prima cutting Laser, Amada CNC Press Brake and more - all located at our facility.

We utilize welding power supplies from Lincoln Electric, Miller, Fronius, and OTC Daihen. We can assist in the proper selection of welding power supply based on your process needs.

Standard system controls from Allen Bradley / Rockwell Automation include CompactGuardlogix PLC with safety-ladder, Ethernet I/P communication and integration with the robot(s) in the cell, color touch-screen HMI with program recipes, welding fixture integration and support. We utilize Rockwell Studio 5000 software and PanelBuilder software. Each robot system is also shipped with the ability for remote PLC support.

Case Studies

Coming Soon